The Process of Creating Custom Ceramic Crowns

From Digital Modeling to Final Finishing

Ceramic crowns are a popular choice for dental restorations due to their natural appearance and durability. At Modern Methods Dental Lab, the process of creating custom ceramic crowns is a blend of advanced technology and skilled craftsmanship, ensuring that each crown is tailored to the individual patient's needs.

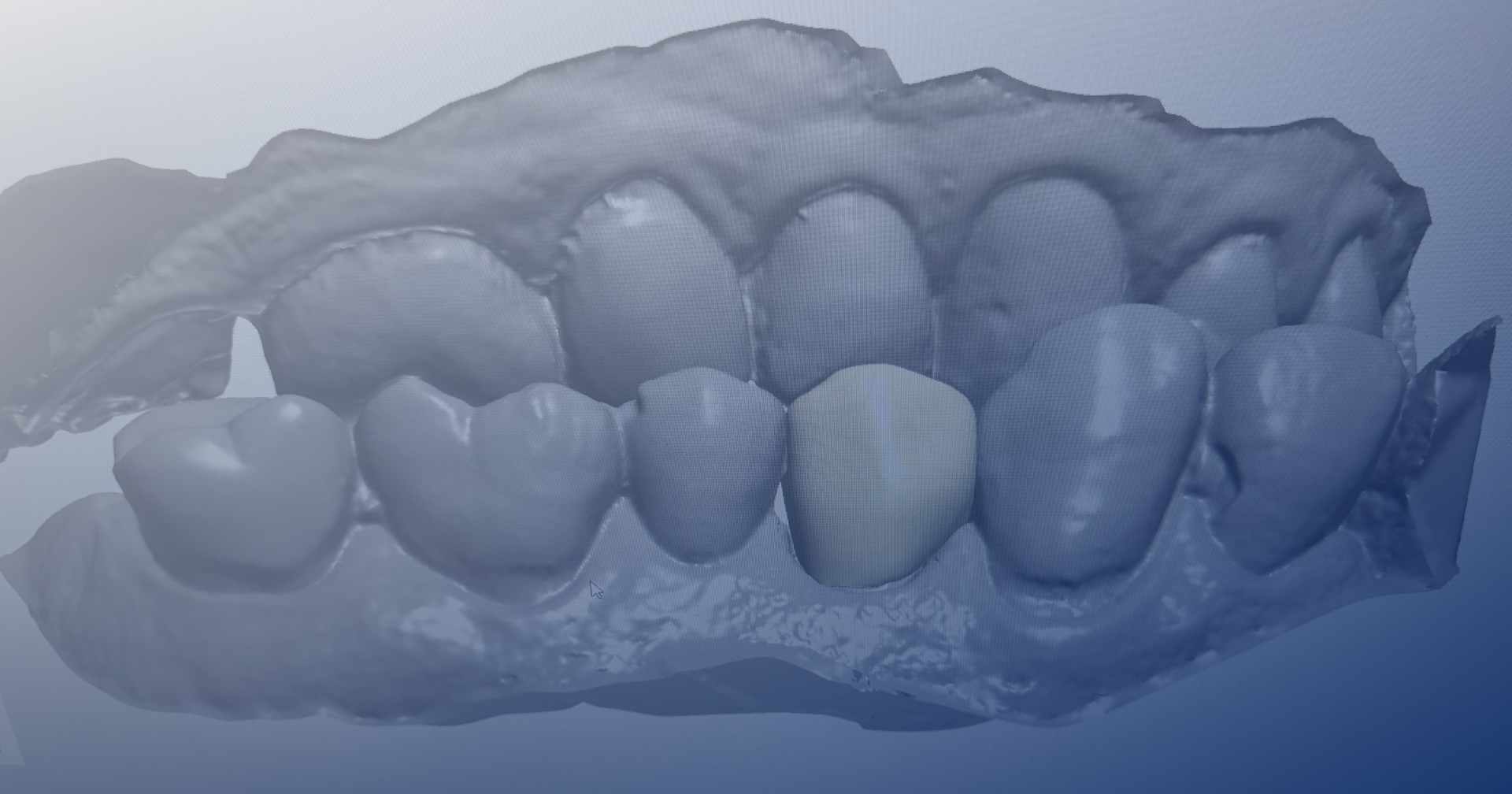

The process begins with digital modeling. After receiving the digital impression from the dentist, our technicians use CAD/CAM software to design a crown that perfectly fits the patient’s tooth structure. This digital model ensures a precise fit and minimizes the need for adjustments once the crown is placed.

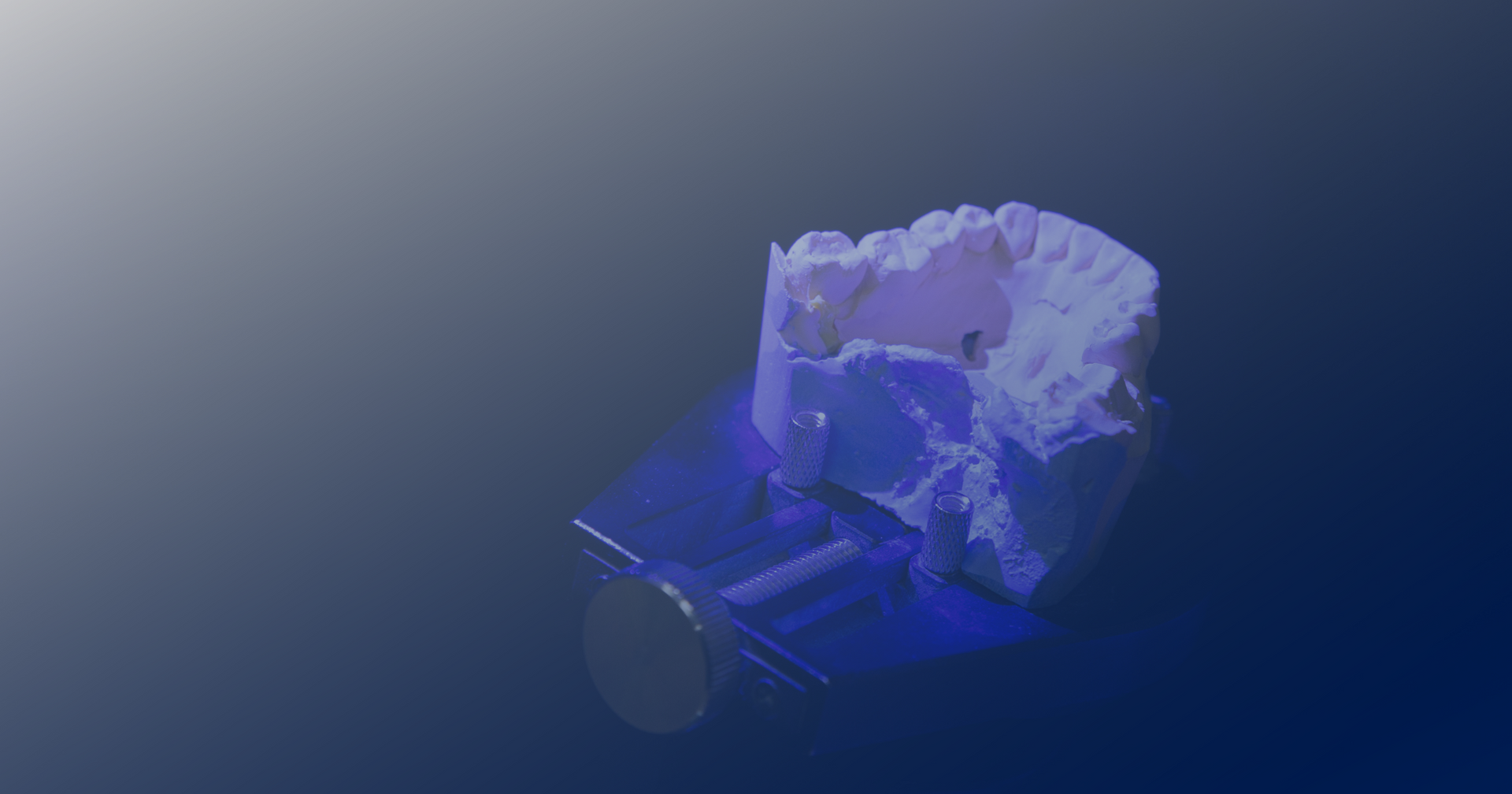

Next, the designed model is sent to our advanced milling machines, where the crown is meticulously crafted from a block of high-quality ceramic material. The milling process is precise, resulting in a crown that matches the contours and dimensions specified in the digital model.

After milling, the crown undergoes finishing touches. Our skilled technicians hand-paint the crown to match the natural color of the patient’s teeth, adding layers of translucent ceramic to achieve a realistic look. Finally, the crown is fired in a high-temperature oven to enhance its strength and durability.

The process of creating custom ceramic crowns at Modern Methods Dental Lab combines cutting-edge technology with expert craftsmanship. The result is a high-quality, durable crown that provides a natural-looking solution for dental restoration.